What are the advantages of such a system?Protection systems will safeguard your site by providing your crane operator with an early warning system that allows them to anticipate and prevent accidents before they happen.

Everybody who’s worked on a construction site with a crane knows that the space to safely operate cranes is getting tighter and tighter. And as spaces narrow, work-place hazards, such as public transit assets, air rights, or an overlapping radius with adjoining cranes and/or high-voltage energized conductors become a much larger problem. Our anti-collision, boundary and zone protection system is an engineered device providing crane operators with early warning detection designed to anticipate collisions through audible and visual cues. Our system is more effective than traditional Safe Work Procedures and radio operated communication protocols because they provide real-time information about what’s going on within the crane’s radius. The system is fully automated, enabling itself as soon as the crane operator initiates motion. Our anti-collision, boundary and zone protection systems are used by crane operators all over the world and have been endorsed by many major companies over the years. Many regulatory bodies have studied the positive impact our systems have produced, and many have now made them a requirement under their respective jurisdictions. Every system installed over the last ten years, when used correctly, has resulted in zero reported collisions.

As a developer you can save tens of thousands of dollars in site prep alone without taking into consideration the savings related to downtime following inadvertent contacts.

By choosing to install our systems, you will, in most cases, no longer need to cover powerlines within the radius of a crane as long as the limits of approach can be maintained. This system can also on occasion, prevent the requirement for mandatory Public Transit Monitors when limits of approach to lower voltage DC Lines can be maintained. |

Eliminate site hazards through engineering.

What are the advantages of the TAC-3000 system over the competition?

|

Our systems can be installed on all makes,

models and years of cranes in operation today.

We are confident in our product, are the North American distributor for this product and have now installed all over Canada and the United States for over 10 years.

Are you a site manager?

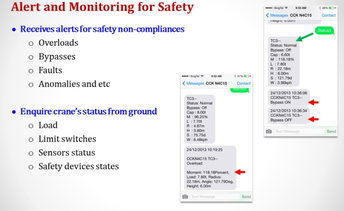

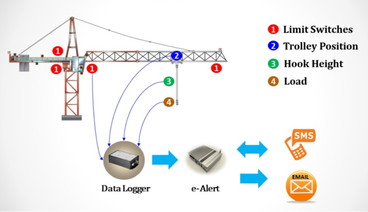

The Tac-3000 is also able to generate reports that allow you to know how efficiently your site’s cranes are operating, such as specific data about how many detections happened within a period. We also can provide SMS notifications of By-Pass status as well as black box recording to assist with any investigations which may happen on a tower crane. Our efforts are continuing with Insurance companies to acknowledge the benefits for sites that use these systems and possibly get a preferred insurance rate with our systems.

The addition of the TAC-3000 along with all its benefits also allows crane owners to bring their cranes up to date in available technology such as radius indicators, LMI, limit and protection devices on all crane makes and models.

Since its introduction, the TAC-3000 has been creating safety awareness in the industry and has been well received by tower crane manufacturers, rental companies, and construction companies around the world. The TAC-3000 system is a trusted technology that has been used to protect some of the most sensitive job sites.

The TAC-3000 exceeds all national and international requirements for safety devices and outperforms all competitor systems.

The TAC-3000 is a fully computerized anti-collision safety system for tower cranes that detects and anticipates the risk of hook block/hoist cable to jib or counter jib collision when multiple tower cranes are in use. When the risk of a tower crane collision is detected, the TAC-3000 safety system will calculate the relative distance in real-time between potential collision paths and send a signal to the other cranes, as well as alerting the operator with the collision information on the LCD monitor and audibly. This includes the collision direction and the identity of the colliding tower crane. At the same time, should the operator not react, the TAC-3000 is designed to automatically decelerate and stop the tower crane’s movement to prevent the collision. Slow, cut, and brake parameters are customizable distances that can be tailored to any crane’s specifications.

The TAC-3000 allows the operation of the tower crane to remain in the operator’s control until safe distances are breached. The tower crane operator maintains the ability to swing the tower crane in the opposite direction of the collision path at all times.

The addition of the TAC-3000 along with all its benefits also allows crane owners to bring their cranes up to date in available technology such as radius indicators, LMI, limit and protection devices on all crane makes and models.

Since its introduction, the TAC-3000 has been creating safety awareness in the industry and has been well received by tower crane manufacturers, rental companies, and construction companies around the world. The TAC-3000 system is a trusted technology that has been used to protect some of the most sensitive job sites.

The TAC-3000 exceeds all national and international requirements for safety devices and outperforms all competitor systems.

The TAC-3000 is a fully computerized anti-collision safety system for tower cranes that detects and anticipates the risk of hook block/hoist cable to jib or counter jib collision when multiple tower cranes are in use. When the risk of a tower crane collision is detected, the TAC-3000 safety system will calculate the relative distance in real-time between potential collision paths and send a signal to the other cranes, as well as alerting the operator with the collision information on the LCD monitor and audibly. This includes the collision direction and the identity of the colliding tower crane. At the same time, should the operator not react, the TAC-3000 is designed to automatically decelerate and stop the tower crane’s movement to prevent the collision. Slow, cut, and brake parameters are customizable distances that can be tailored to any crane’s specifications.

The TAC-3000 allows the operation of the tower crane to remain in the operator’s control until safe distances are breached. The tower crane operator maintains the ability to swing the tower crane in the opposite direction of the collision path at all times.

Technology

The TAC-3000 is also ideal for companies that have older tower cranes that are in perfect operating condition and need to be updated with the latest easy to use technology in order to compete with newer cranes in their respective market.

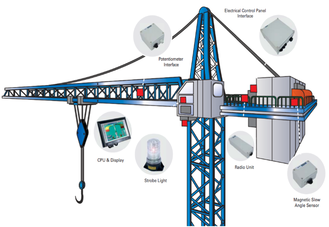

The TAC-3000 is a fully computerized LMI system for tower cranes. It features swing angle indication, trolley position, hook height, load weight, event recording, and crane status including neighboring crane status when multiple cranes are in use.

The TAC-3000 is the worlds most advanced LMI system for tower cranes available and is the easiest LMI system to install and the most accurate in determining the weight on the hook.

The TAC-3000 utilizes CAN bus for inter-module communication and the latest positioning technology via a magnetic sensor that measures the earth’s magnetic flux in real- time. The TAC-3000 utilizes a 32-bit CPU, FCC approved wireless components and reliable PC based technology. The TAC-3000 also communicates wirelessly between cranes and any preset information can be uploaded wirelessly through a PC. The TAC-3000 uses 128-bit data encryption integrated into the software with a USB dongle and a 32-bit CPU to build the highest security measure available.

With state-of-the-art technology, the TAC-3000 allows site safety personnel to monitor the cranes in operation from the ground with the optional TAC-View. The settings of the crane’s protection parameters and protection areas can also be adjusted wirelessly from ground level. For example, when climbing up the crane’s height or to add an additional protection zone, authorized personnel will only be required to upload the new height to the crane from a laptop PC without having to climb the tower crane for “re-teaching.” This effectively reduces the downtime of the crane’s operation, an important factor for site management. Besides the advanced wireless features, the TAC-3000 has also successfully eliminated the need to perform on-site “teaching” of the collision paths. Authorized personnel just need to input the necessary information into their PC and wirelessly upload the settings to the cranes from ground level.

The TAC-3000 is a fully computerized LMI system for tower cranes. It features swing angle indication, trolley position, hook height, load weight, event recording, and crane status including neighboring crane status when multiple cranes are in use.

The TAC-3000 is the worlds most advanced LMI system for tower cranes available and is the easiest LMI system to install and the most accurate in determining the weight on the hook.

The TAC-3000 utilizes CAN bus for inter-module communication and the latest positioning technology via a magnetic sensor that measures the earth’s magnetic flux in real- time. The TAC-3000 utilizes a 32-bit CPU, FCC approved wireless components and reliable PC based technology. The TAC-3000 also communicates wirelessly between cranes and any preset information can be uploaded wirelessly through a PC. The TAC-3000 uses 128-bit data encryption integrated into the software with a USB dongle and a 32-bit CPU to build the highest security measure available.

With state-of-the-art technology, the TAC-3000 allows site safety personnel to monitor the cranes in operation from the ground with the optional TAC-View. The settings of the crane’s protection parameters and protection areas can also be adjusted wirelessly from ground level. For example, when climbing up the crane’s height or to add an additional protection zone, authorized personnel will only be required to upload the new height to the crane from a laptop PC without having to climb the tower crane for “re-teaching.” This effectively reduces the downtime of the crane’s operation, an important factor for site management. Besides the advanced wireless features, the TAC-3000 has also successfully eliminated the need to perform on-site “teaching” of the collision paths. Authorized personnel just need to input the necessary information into their PC and wirelessly upload the settings to the cranes from ground level.

Data RecordingIn today’s world, data is key to success. The quality of data collected can allow to significantly increase operational effectiveness as well as safety. Should an inadvertent accident occur, Management also has data to reconstruct the moments prior to the event and ensure proper safeguards are implemented to avoid reoccurrence.

|

Why is Data Management, Non-volatility and Redundancy Important?

Despite these systems being mandated in more and more jurisdictions, they are often bypassed, not properly programmed or when requiring troubleshooting, no time is allotted to troubleshoot them. In the end, this puts all levels of management in a vulnerable position thinking they are protected while they may not be.